Information

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.

2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simulation of aerospace systems, enabling engineers to optimize performance, diagnose issues, and predict maintenance needs. This predictive maintenance approach can help minimize downtime and prevent costly repairs.

3. Utilizing additive manufacturing: Additive manufacturing, also known as 3D printing, has revolutionized the aerospace industry by enabling the rapid production of complex components. By using this technology, manufacturers can reduce lead times, minimize waste, and produce lightweight parts that are both durable and efficient.

4. Incorporating advanced materials: Advanced materials, such as carbon fiber composites and ceramic matrix composites, offer improved strength-to-weight ratios and thermal properties, making them ideal for use in aerospace applications. By incorporating these materials into aircraft structures, engines, and components, companies can achieve greater fuel efficiency and performance.

5. Optimizing supply chain management: Efficient supply chain management is crucial for ensuring timely deliveries of components and materials to assembly lines. By implementing advanced logistics systems and leveraging data analytics, aerospace companies can streamline their supply chains, reduce lead times, and improve overall efficiency.

6. Investing in research and development: Continuous innovation is key to enhancing efficiency in aerospace technologies. By investing in research and development initiatives, companies can develop cutting-edge technologies, improve processes, and stay ahead of the competition.

7. Embracing sustainability: As the aerospace industry faces increasing pressure to reduce its environmental impact, companies are turning to sustainable practices to improve efficiency. This includes developing eco-friendly fuels, designing more fuel-efficient aircraft, and minimizing waste in manufacturing processes. By prioritizing sustainability, aerospace companies can improve their efficiency while also reducing their carbon footprint.

Overall, by embracing advanced technologies, optimizing processes, and prioritizing sustainability, aerospace companies can enhance their efficiency and stay competitive in the evolving industry.

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

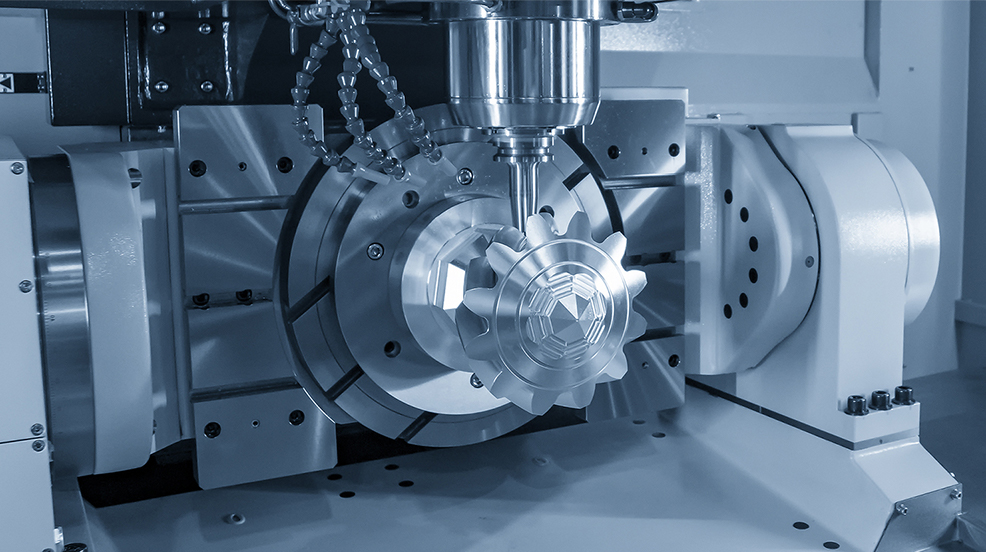

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

Shape accuracy detection

In addition to dimensional accuracy, the shape accuracy of the parts cannot be ignored. Detect shape errors such as roundness, cylindricity, and flatness of parts using equipment such as roundness meters and contour meters. For example, when processing high-precision bearing rings, the accuracy of roundness and cylindricity directly affects the rotational accuracy and service life of the bearing.

Dimensional accuracy testing

Using advanced measuring tools and techniques, such as coordinate measuring instruments, optical imagers, etc., to accurately measure the dimensions of parts. For precision parts, dimensional tolerances are usually controlled at the micrometer level, so high-precision measuring equipment is required to ensure the accuracy of the test results. For example, when processing precision molds for mobile phone chi...

- +86 13603025252

-

WhatsApp

- info@jiujucnc.com