Information

Precision Parts Processing Set to Transform Manufacturing Efficiency

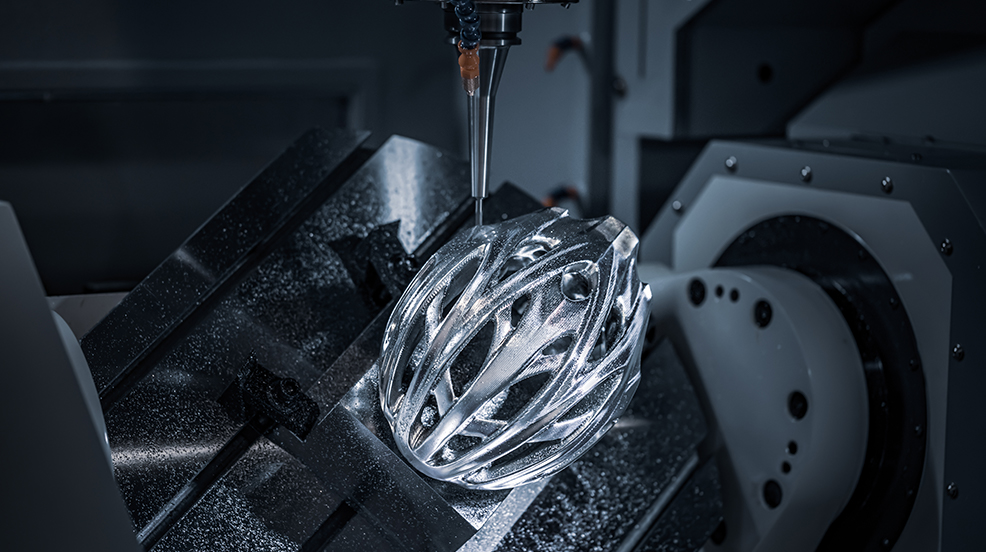

Precision parts processing is a manufacturing process that involves the use of advanced machining techniques to produce highly accurate and complex components. This process has the potential to significantly improve manufacturing efficiency by increasing the speed and accuracy of production, while also reducing the costs associated with traditional machining methods.

One of the key advantages of precision parts processing is the ability to produce high-quality components with a high degree of accuracy. This can result in fewer errors and defects, leading to improved product quality and customer satisfaction. Additionally, the use of advanced machining techniques allows for faster production times, which can help companies meet tight deadlines and increase their overall output.

Another benefit of precision parts processing is the ability to reduce waste and conserve resources. By using advanced machining techniques, manufacturers can minimize material waste and ensure that each component is produced with the highest level of precision. This can lead to significant cost savings and a more sustainable manufacturing process overall.

Overall, precision parts processing has the potential to transform the manufacturing industry by improving efficiency, increasing quality, and reducing costs. As technology continues to advance, we can expect to see even greater advancements in precision parts processing that will further enhance the capabilities of manufacturers and help them stay competitive in an increasingly global market.

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

Shape accuracy detection

In addition to dimensional accuracy, the shape accuracy of the parts cannot be ignored. Detect shape errors such as roundness, cylindricity, and flatness of parts using equipment such as roundness meters and contour meters. For example, when processing high-precision bearing rings, the accuracy of roundness and cylindricity directly affects the rotational accuracy and service life of the bearing.

Dimensional accuracy testing

Using advanced measuring tools and techniques, such as coordinate measuring instruments, optical imagers, etc., to accurately measure the dimensions of parts. For precision parts, dimensional tolerances are usually controlled at the micrometer level, so high-precision measuring equipment is required to ensure the accuracy of the test results. For example, when processing precision molds for mobile phone chi...

- +86 13603025252

-

WhatsApp

- info@jiujucnc.com