Information

Precision Machining: The Backbone of Modern Manufacturing

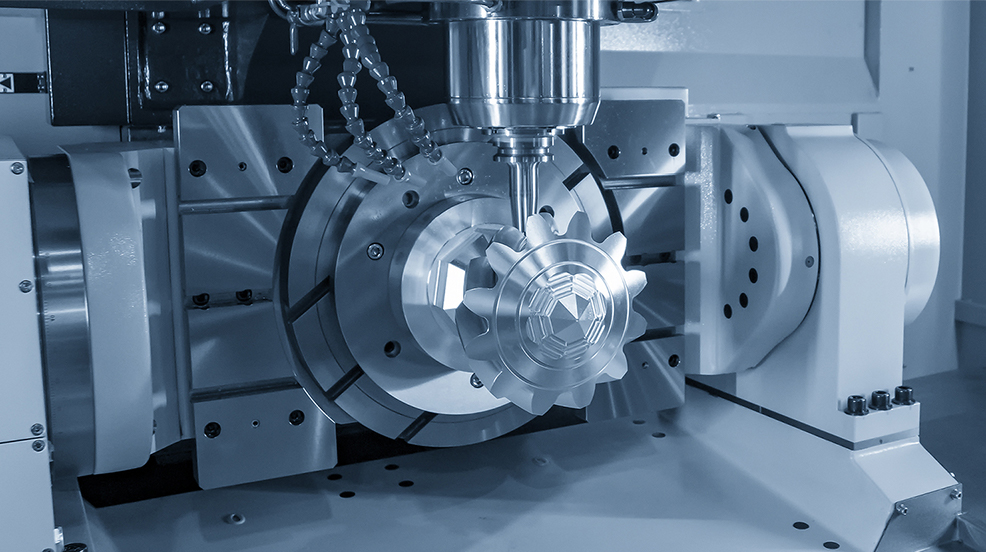

In the realm of modern manufacturing, precision machining stands as a cornerstone technology, enabling the production of intricate and high - tolerance components that power a wide range of industries. Precision machining refers to the process of fabricating parts with extremely tight dimensional tolerances, often measured in micrometers or even nanometers. This level of accuracy is crucial for the proper functioning of complex machinery, from aerospace engines to medical devices.

One of the key aspects of precision machining is the use of advanced CNC (Computer Numerical Control) machines. These machines are programmed to execute highly precise cutting, milling, turning, and drilling operations. CNC technology eliminates human error associated with manual machining, ensuring consistent and repeatable results. For example, in the automotive industry, precision - machined engine parts such as pistons and crankshafts require tight tolerances to optimize engine performance and fuel efficiency. A slight deviation in the dimensions of these parts could lead to reduced power output, increased emissions, and even engine failure.

Another important factor in precision machining is the choice of materials. Different materials have varying properties that can affect the machining process and the final quality of the part. For instance, metals like titanium and nickel alloys are widely used in aerospace applications due to their high strength - to - weight ratio. However, these materials are also difficult to machine because of their hardness and tendency to work - harden. Machinists must carefully select cutting tools and machining parameters to ensure successful processing. Advanced cutting tools made from materials like carbide and ceramic are often used to achieve the required precision when working with such challenging materials.

Quality control is an integral part of precision machining. Manufacturers employ a variety of inspection techniques to verify the accuracy of machined parts. Coordinate Measuring Machines (CMMs) are commonly used to measure the dimensions of a part with high precision. These machines use probes to scan the surface of the part and compare the measured values with the design specifications. Any deviations are then corrected through additional machining or adjustment of the manufacturing process. In addition to dimensional inspection, surface finish is also a critical parameter in precision machining. A smooth surface finish is essential for parts that require tight fits or reduced friction, such as bearings and seals.

The applications of precision - machined parts are vast and far - reaching. In the medical field, precision machining is used to create custom - made implants and surgical instruments. The high level of accuracy ensures a perfect fit for implants, reducing the risk of rejection and improving patient outcomes. Surgical instruments, on the other hand, require sharp edges and precise geometries to perform delicate procedures with minimal trauma. In the electronics industry, precision - machined components are used in the production of microchips, connectors, and other electronic devices. The miniaturization trend in electronics demands parts with extremely small dimensions and high precision to ensure proper functionality.

In conclusion, precision machining is a highly specialized and essential field in modern manufacturing. It combines advanced technology, skilled craftsmanship, and strict quality control to produce parts that meet the most demanding requirements. As technology continues to evolve, the demand for even more precise and complex parts will only increase, driving further innovation in the field of precision machining.

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

Shape accuracy detection

In addition to dimensional accuracy, the shape accuracy of the parts cannot be ignored. Detect shape errors such as roundness, cylindricity, and flatness of parts using equipment such as roundness meters and contour meters. For example, when processing high-precision bearing rings, the accuracy of roundness and cylindricity directly affects the rotational accuracy and service life of the bearing.

Dimensional accuracy testing

Using advanced measuring tools and techniques, such as coordinate measuring instruments, optical imagers, etc., to accurately measure the dimensions of parts. For precision parts, dimensional tolerances are usually controlled at the micrometer level, so high-precision measuring equipment is required to ensure the accuracy of the test results. For example, when processing precision molds for mobile phone chi...

- +86 13603025252

-

WhatsApp

- info@jiujucnc.com