Information

The Art and Science of Precision Machining

Precision machining is not just a mechanical process; it is a harmonious blend of art and science. It requires a deep understanding of engineering principles, materials science, and the skills of a master craftsman to create components with micron - level accuracy.

At the heart of precision machining is the concept of tolerance. Tolerance refers to the acceptable range of variation in the dimensions of a part. In precision machining, these tolerances are often extremely tight. For example, in the manufacturing of optical lenses, the surface curvature and thickness must be within a few micrometers of the design specifications to ensure proper optical performance. Achieving such tight tolerances involves careful control of every aspect of the machining process, from the selection of cutting tools to the environmental conditions in the machining workshop.

The science behind precision machining lies in the use of advanced manufacturing technologies. High - speed machining, for example, allows for faster material removal while maintaining high precision. This is achieved by using specialized cutting tools and optimizing the cutting parameters such as spindle speed, feed rate, and depth of cut. Another important technology is electrical discharge machining (EDM), which is used to machine complex shapes in hard materials. EDM works by creating electrical discharges between an electrode and the workpiece, eroding the material away in a controlled manner.

However, technology alone is not enough. The art of precision machining lies in the hands of the machinist. A skilled machinist has an intuitive understanding of how the machine works, how the materials respond to different machining operations, and how to troubleshoot any issues that may arise during the process. They can make real - time adjustments to the machining parameters based on their experience and observation, ensuring that the final part meets the required specifications.

Precision machining also plays a crucial role in the development of new technologies. For example, in the field of renewable energy, precision - machined parts are used in wind turbines and solar panels. The high - precision components in wind turbines, such as gearboxes and bearings, are essential for efficient power generation and long - term reliability. In solar panels, precision - machined frames and connectors ensure proper alignment and electrical connection, maximizing the energy conversion efficiency.

In the defense industry, precision - machined parts are used in the production of weapons systems, aircraft, and naval vessels. The reliability and performance of these military equipment depend on the accuracy of the machined components. For example, the barrels of firearms require precise machining to ensure consistent bullet trajectories and accuracy.

Despite its many advantages, precision machining also faces challenges. The cost of advanced machining equipment and the need for highly skilled labor can be a barrier for some manufacturers. Additionally, the increasing demand for smaller and more complex parts requires continuous innovation in machining techniques.

In conclusion, precision machining is a fascinating field that combines the latest scientific advancements with the traditional skills of craftsmanship. As technology continues to advance, precision machining will continue to play a vital role in shaping the future of manufacturing, enabling the production of innovative products that improve our lives in countless ways.

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

Enhancing Efficiency in Aerospace Technologies

1. Implementing advanced automation and robotics: By utilizing automated systems and robotics in aerospace technologies, tasks can be performed more quickly and accurately, leading to increased efficiency. This includes automated systems for manufacturing, inspection, maintenance, and handling of materials.2. Adopting digital twin technology: Digital twin technology allows for real-time monitoring and simul...

Cutting-edge Machining of Unique Materials

Advancements in technology have allowed for the cutting-edge machining of unique materials that were previously difficult to work with. This has opened up new possibilities for manufacturing industries, allowing for the production of components and products that were once thought to be impossible.One such material that has benefited from cutting-edge machining techniques is carbon fiber. Carbon fiber is a l...

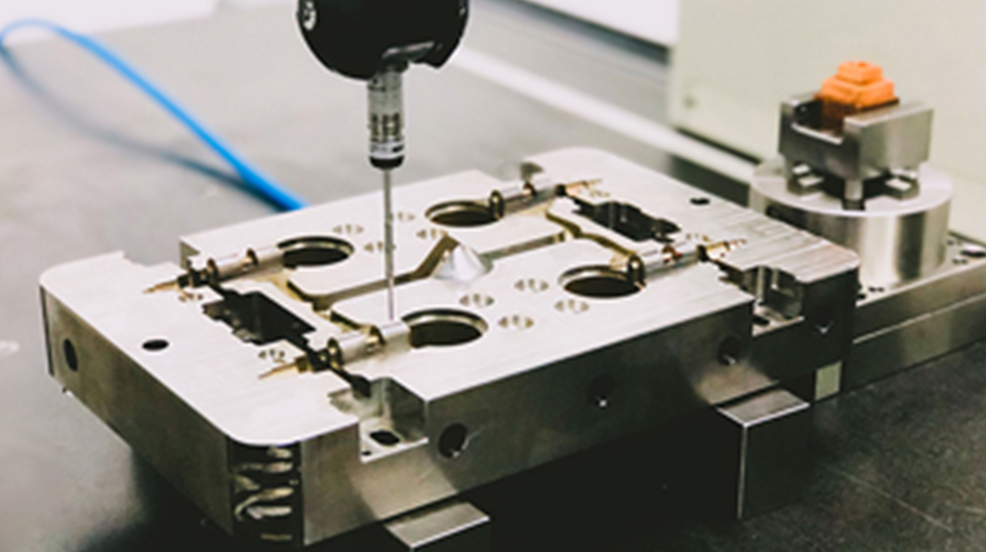

Shape accuracy detection

In addition to dimensional accuracy, the shape accuracy of the parts cannot be ignored. Detect shape errors such as roundness, cylindricity, and flatness of parts using equipment such as roundness meters and contour meters. For example, when processing high-precision bearing rings, the accuracy of roundness and cylindricity directly affects the rotational accuracy and service life of the bearing.

Dimensional accuracy testing

Using advanced measuring tools and techniques, such as coordinate measuring instruments, optical imagers, etc., to accurately measure the dimensions of parts. For precision parts, dimensional tolerances are usually controlled at the micrometer level, so high-precision measuring equipment is required to ensure the accuracy of the test results. For example, when processing precision molds for mobile phone chi...

- +86 13603025252

-

WhatsApp

- info@jiujucnc.com