FAQ

Nano-structured surface machining for advanced tribology

What is the difference between cnc and CNC lathe there?

CNC (Computer Numerical Control) and CNC lathe are two important concepts in the field of machining and there are many differences between them.Firstly, on a conceptual level, CNC is a type of control. It uses computer programmes to precisely control the movements of the machine tool, including tool trajectories, speeds, feeds, and many other parameters.CNC technology is like an intelligent brain that can e...

Difference between CNC lathe and machining centre?

1. Functional aspectsCNC lathe: mainly used for processing rotary body parts, such as shafts and disc parts. It is processed around the workpiece rotating spindle. For example, processing a cylindrical shaft, CNC lathe can accurately turn the outer circle, inner hole, tapered surface, threads, and so on. The shape of its machining is mainly achieved by the linear or arc movement of the tool on the surface o...

Re-machining allowances for progressive stamping dies_

Re-machining Allowances for Progressive Stamping Dies In the precision manufacturing industry, re-machining allowances play a critical role in ensuring the longevity, accuracy, and performance of progressive stamping dies. These allowances refer to the additional material intentionally left during the initial manufacturing process to accommodate potential repairs, adjustments, or re-machining i...

Rapid tooling solutions during material shortage crises

Rapid Tooling Solutions in Material Shortage Crises In the face of global material shortages, the manufacturing industry faces unprecedented challenges in maintaining production timelines and costs. As a specialized precision parts, I emphasize the importance of rapid tooling solutions (RTS) as a critical strategy to mitigate these disruptions. RTS leverages advanced technologies, such as 3D pr...

Autonomous Driving Radars | Mirror Surface Ultra-Precision Machining (Ra≤0.1μm)_ 20% Longer Detection Range

Autonomous Driving Radars | Mirror Surface Ultra-Precision Machining (Ra≤0.1μm): 20% Longer Detection Range Autonomous Driving Radars | Mirror Surface Ultra-Precision Machining (Ra≤0.1μm): 20% Longer Detection Range The world of autonomous driving technology is evolving at a rapid pace, and one of the key components driving this advancement is the radar system. Autono...

Automotive Sensors | MEMS Wafer Dicing (Precision ±0.003mm)_ Faster Signal Response

Automotive Sensors | MEMS Wafer Dicing (Precision ±0.003mm): Faster Signal Response Automotive Sensors | MEMS Wafer Dicing (Precision ±0.003mm): Faster Signal Response In the ever-evolving automotive industry, sensors play a crucial role in enhancing vehicle performance, safety, and driver experience. Automotive sensors are integral components in systems such as advan...

-

Re-machining allowances for progressive stamping dies_

-

Rapid tooling solutions during material shortage crises

-

Quantum computing applications in machining simulations

-

Preventing sink marks in injection mold core machining_

-

Preventing delamination in carbon fiber composite milling

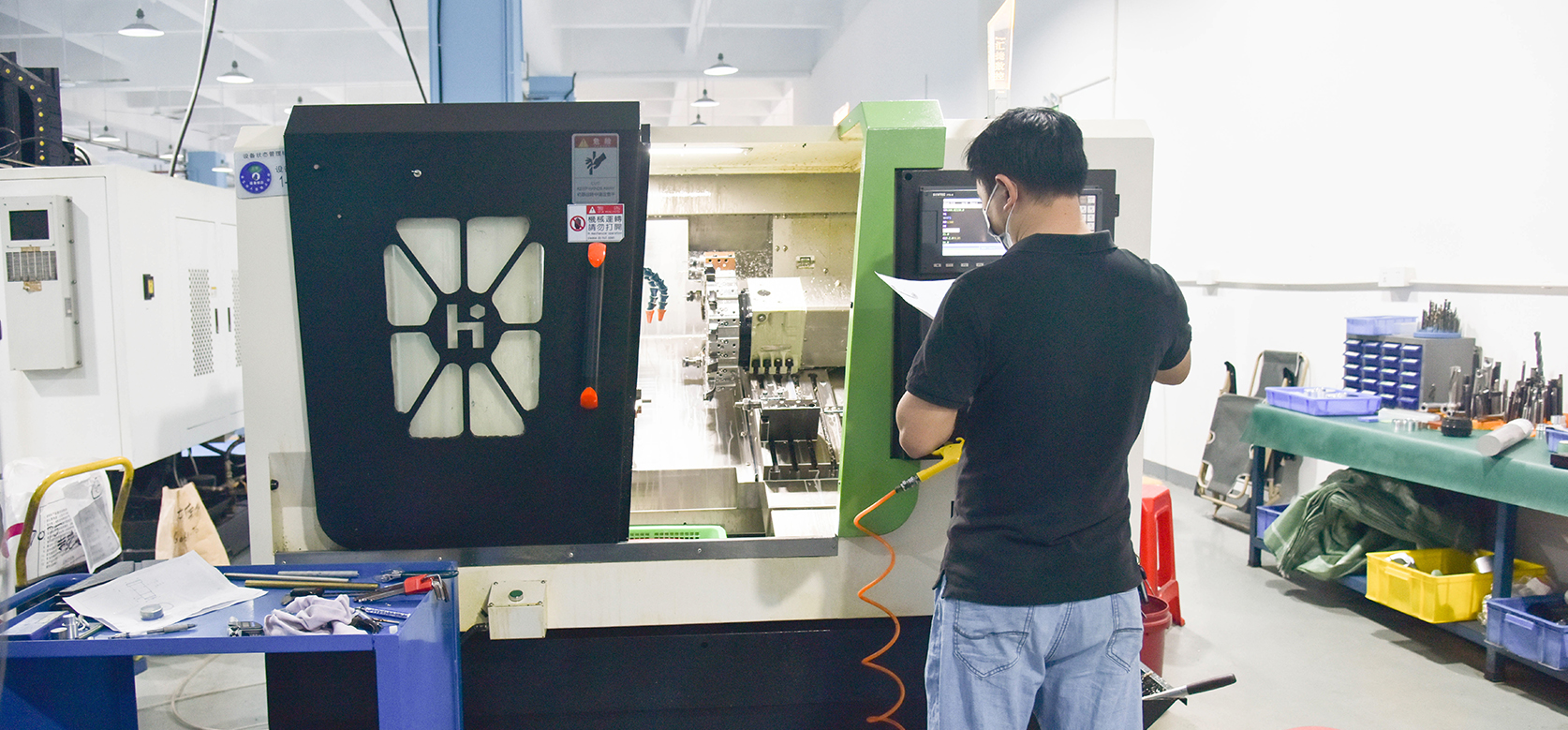

Precision CNC Turning Solutions: Engineering Excellence for Critical ApplicationsWhen your projects demand micron-level accuracy and repeatability, our Swiss-Type CNC turning expertise delivers:Efficiently and ...

When your parts face these critical challenges, we deliver industrial-grade answers:"How to machine 0.1mm-thick turbine blade walls with deformation < ±0.005mm?""Achieving Ra 0.4μm mirror fini...

Milling can process various shapes such as flat surfaces and grooves, with an accuracy of IT7-IT9 level and a surface roughness of 1.6-6.3 μ m.The grinding accuracy reaches IT5-IT7 level, with a surface roughne...

Our mechanical component processing has very strict management and control in the design stage, material selection, processing technology planning, manufacturing, surface treatment and protection, quality inspe...

- +86 13603025252

-

WhatsApp

- info@jiujucnc.com